Anti-Foam Control Solutions-- Trustworthy Foam Control for Chemical Handling

Anti-Foam Control Solutions-- Trustworthy Foam Control for Chemical Handling

Blog Article

Finest Practices for Picking the Right Anti-Foam Control Option for Your Demands

Choosing a reliable anti-foam control service demands an extensive analysis of your distinct functional requirements. Secret factors to consider include the certain residential properties of your procedure, such as ph, chemical, and temperature communications, all of which substantially affect the performance of defoaming agents. Guaranteeing compatibility with the tool and sticking to governing criteria are important for effective application. As we discover these critical elements, it ends up being obvious that the ideal selections can bring about not just prompt advantages but also long-term operational improvements that warrant further evaluation.

Understand Your Foam Trouble

Often, organizations encounter foam-related concerns that can prevent operational efficiency and product top quality. Foam formation can occur throughout different processes, consisting of blending, fermenting, and transportation, and it often brings about tools ineffectiveness, production downtime, and raised operational costs. Recognizing the underlying causes of foam generation is essential for addressing the issue efficiently.

Foam can arise from a number of factors, such as the nature of the products included, frustration levels, temperature level variations, and chain reactions. Particular surfactants can intensify frothing, while high shear mixing can present air, leading to unwanted foam accumulation. In addition, environmental problems and the particular qualities of the liquid systems being used can considerably affect foam behavior.

Recognizing the kind of foam-- whether it is steady or unpredictable-- is additionally vital. Secure foam tends to continue longer and is extra challenging to handle, while unpredictable foam may dissipate much more quickly. Anti-Foam Control Solutions. By assessing these variables, organizations can get understandings right into their foam issues, enabling them to establish targeted approaches to mitigate foam formation and improve total procedure efficiency. This foundational understanding is important for choosing a proper anti-foam control solution customized to details functional needs.

Review Anti-Foam Options

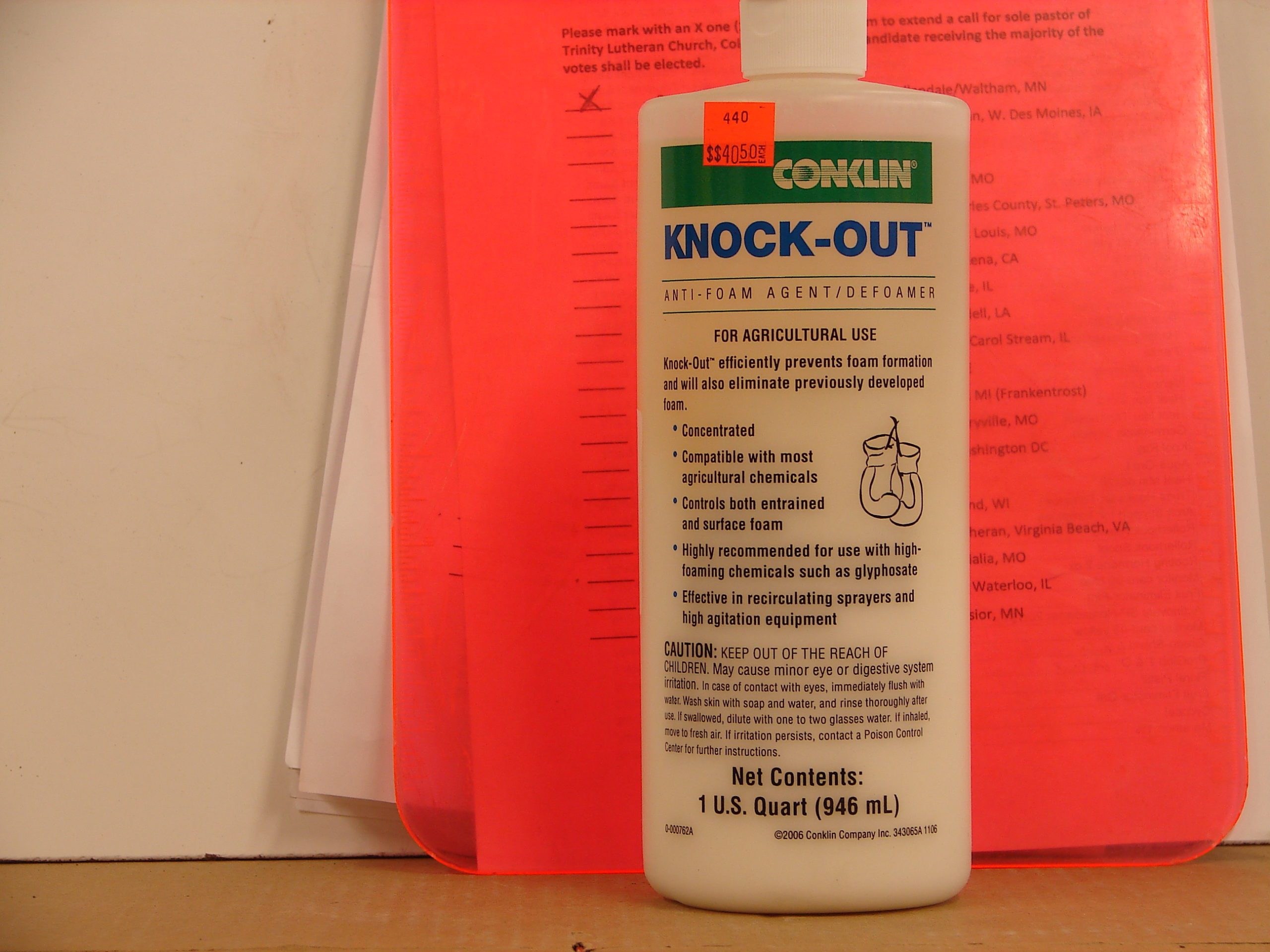

When taking into consideration anti-foam alternatives, it is essential to thoroughly evaluate the numerous solutions readily available on the marketplace to discover the most suitable solution for your specific foam-related obstacles. Anti-foam representatives been available in diverse types, including silicone-based, non-silicone, and all-natural formulas, each offering unique residential properties and efficiency qualities.

Begin by assessing the specific application needs, such as temperature level thresholds, pH degrees, and the sort of foam being produced. Silicone-based agents are recognized for their efficiency in high-temperature environments, while non-silicone alternatives may be better in food handling applications due to regulatory factors to consider.

It is also critical to think about the rate of application and the wanted longevity of the foam control. Some solutions may give instant defoaming activity, while others provide long term stability. Performing small-scale examinations can offer understandings into the efficiency of each option in real-world conditions.

Take Into Consideration Application Compatibility

In the world of anti-foam options, making sure application compatibility is vital for accomplishing optimal performance. The performance of an anti-foam representative mainly depends on its ability to operate sympathetically within the particular parameters of your application, consisting of temperature level, pH, and the existence of other chemicals. Various formulas may execute variably throughout diverse problems, therefore extensive testing is essential.

Begin by recognizing the attributes of your process, such as see this page thickness and the nature of the medium in which the anti-foam will certainly be utilized. Some anti-foam agents might work well in liquid options but stop working in organic solvents. In addition, think about the potential interactions with existing components and materials to prevent unfavorable effects.

It is additionally crucial to assess the method of application. Whether the anti-foam is presented constantly or batch-wise can influence its effectiveness and longevity in the system. Ensure that the picked product is not only suitable with the operational specifications yet also straightens with any regulative needs important to your sector.

Assess Environmental Impact

Exactly how does the ecological impact of an anti-foam control service affect your overall choice procedure? The ecological impact of your selected anti-foam representative is paramount, as it shows your dedication to sustainability and governing compliance. Selecting a product with very little ecological my site effects can enhance your company image and foster customer count on.

When analyzing ecological impact, consider the biodegradability of the anti-foam service. Eco-friendly alternatives are generally preferable, as they break down much more quickly and minimize long-lasting eco-friendly injury. In addition, review the possibility for bioaccumulation and poisoning to marine life. Solutions with high poisoning can pose significant risks to local communities, potentially resulting in regulatory penalties and ecological destruction.

Another critical variable is the visibility of harmful substances. Anti-foams containing harmful chemicals might require special delivery and disposal measures, raising functional costs and making complex compliance site with ecological guidelines. Choosing environmentally friendly choices can alleviate these risks.

Display and Optimize Efficiency

To make best use of the efficiency of your anti-foam control remedy, it is vital to frequently monitor and enhance its efficiency. Constant analysis enables for the recognition of any variances in foam levels and the subsequent performance of the anti-foam agent.

Carry out a systematic technique to monitor essential efficiency indicators (KPIs), such as foam volume, security, and the response time of the anti-foam agent. Make use of analytical tools and methods, such as aesthetic inspections, foam height dimensions, and specialized sensing units, to gather precise information.

Furthermore, keep open communication with distributors for technical assistance and insights on the most up to date advancements in anti-foam innovation. This proactive technique not just aids in attaining optimal efficiency yet additionally lessens functional disturbances and improves general process effectiveness. Regularly reviewing and improving your anti-foam strategy makes sure that you are properly managing foam-related difficulties, inevitably leading to enhanced performance and price savings.

Conclusion

In final thought, picking the appropriate anti-foam control service demands a comprehensive assessment of certain application demands, consisting of temperature, pH levels, and chemical compatibility. Adhering to these finest techniques will certainly facilitate informed decision-making in anti-foam control services.

Choosing a reliable anti-foam control remedy necessitates a comprehensive assessment of your special functional needs.In the world of anti-foam solutions, guaranteeing application compatibility is critical for accomplishing ideal efficiency.Exactly how does the ecological effect of an anti-foam control option influence your general choice process?In final thought, choosing the suitable anti-foam control service necessitates an extensive assessment of particular application needs, including temperature level, pH degrees, and chemical compatibility (Anti-Foam Control Solutions). Sticking to these finest methods will facilitate informed decision-making in anti-foam control remedies

Report this page